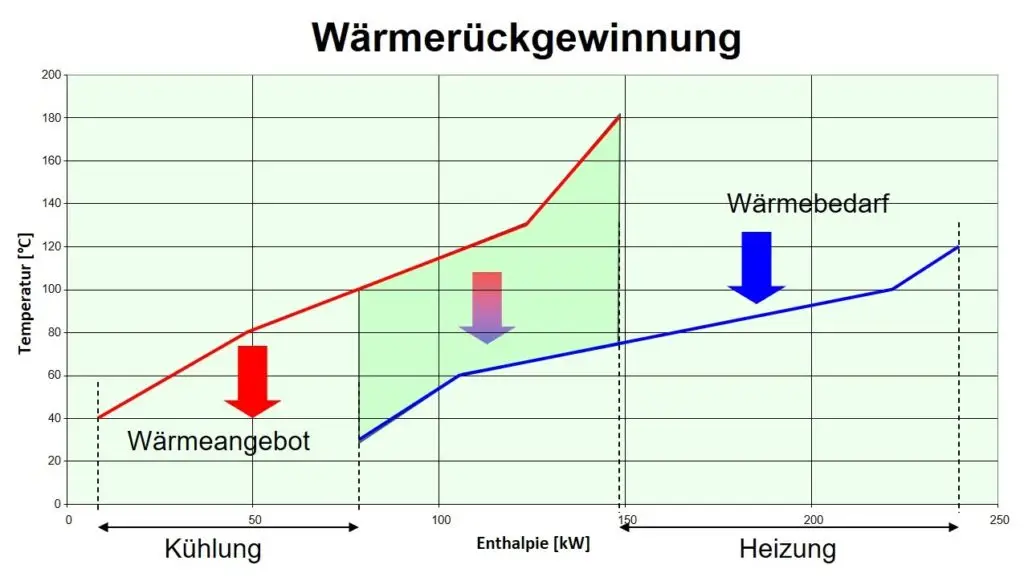

Heat stream optimization via Pinch Analysis

The Pinch Analysis is a systematic approach for optimizing process heat utilization. Developed in the 1980s, this method is grounded in fundamental principles of thermodynamics. Within our projects, we systematically apply this technique and collaborate with our clients to identify measures that reduce the process heat consumption in their facilities.

Energy cost and emission reduction through waste heat utilization

With our systematic approach, we optimize your industrial facilities.

In our projects, the Pinch Analysis is a central tool. However, our holistic approach extends beyond this. We also examine the existing plant layout, using real process data to identify the minimum external energy requirements. While the most significant savings typically arise from optimizing cold and hot streams, additional cost reductions can often be achieved by making adjustments to the plant design that has evolved over the years.

Pinch analysis as a tool for decarbonizing heat supply

Using pinch analysis, the potential for decarbonizing heat supply can be analyzed in a structured manner. On this basis, we work with our customers to identify process modifications that lead to CO2-free plant operation.

Process plants are heat cascades into which heat is fed at high temperatures and from which waste heat is released at different temperatures. The decarbonization of the heat supply of process plants can be successful if waste heat is reused in the process and the remaining, unavoidable heat supply is electrified at high temperatures.